S.H.E.

-

Infrastructure

We are actively implementing improvement on safety devices, safety facilities, and other unsafe conditions by actively discovering the unsafe conditions of worksites and equipment through safety inspection and precision diagnosis involving participation from everyone. We are also leading the creation of a safe worksite by continuously investing in the operation of systematic safety management organization and the expansion of safety facilities.

-

[Safety Inspection with Everyone's Participation]

[Safety Inspection with Everyone's Participation]

- - Permanent mobile inspection team, night patrol of executives/team managers, monthly theme checkup

- - Labor-management joint inspection, safety checkup of worksites, etc.

-

[Precision Safety Diagnosis]

[Precision Safety Diagnosis]

- - Self-regulated inspection of dangerous machines, self-regulated inspection of gas facilities

- - Safety diagnosis for harmful facilities, safety inspection for fire prevention facilities, etc

-

[Expanding the Basis for Safety]

[Expanding the Basis for Safety]

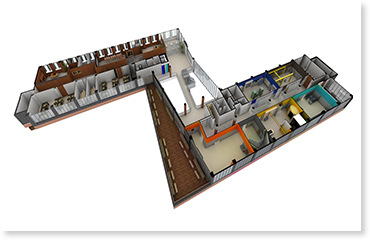

- - Setting up experiential safety training center & integrated disaster prevention center

- - Expansion of safety management organization, operation of fire brigade and safety patrols, etc.

-

-

SYSTEM

We are setting up the foundation for safety and health management system through OHSAS 18001 certification, while discovering and applying successful cases of safety management by benchmarking outstanding domestic and international companies in safety management. Also, while improving the system by performing diagnosis and consulting in partnership with safety specialized agencies, we are running a flawless safety management system by adopting advanced safety management methods.

-

[Safety System]

[Safety System]

- - OHSAS 18001, ILS (Isolation Locking System)

- - PSM (Process Safety Management), safety evaluation in general overhaul, etc.

-

[Benchmarking]

[Benchmarking]

- - Benchmarking advanced overseas safety management company

- - Periodically benchmarking domestic worksites for outstanding safety management

-

[Diagnosis of Safety System]

[Diagnosis of Safety System]

- - Safety consulting with a specialized agency

- - Standardizing system documents and operating procedure

-

-

MIND

Mindful that most accidents are caused by workers' unsafe behavior, we focus on performing activities for raising workers' safety awareness with a view to preventing accidents. We are performing systematic safety training by defining our goal in safety management as ensuring safety not only at worksites but in family while motivating safety through zero-disaster campaign, various rewards, and safety events.

-

[Safety Training]

[Safety Training]

- - Special safety training for top management, experiential safety training, innovative training for safety awareness

- - Safety Coaching, safety training for socially disadvantaged people

-

[Safety Events]

[Safety Events]

- - Challenge!! Safety Green Bell, safety campaign, occupational safety seminar

- - Competition of outstanding cases ofsafety management, UCC competition, etc.

-

[Safety Awards]

[Safety Awards]

- - For departments/companies that have achieved zero disaster, departments/companies with outstanding self-regulated safety management

- - Awards for exemplary safety practicing person, person with excellent participation in safety activities

-