S.H.E.

-

Early Detection

We are operating a highly reliable early detection system, having set up an automatic fire detection and gas leak monitoring system and installed CCTV cameras in select places with high risk of accidents to minimize damage with prompt response when accident occurs. All such early monitoring systems are connected to an integrated disaster prevention center operating 24/7 to monitor abnormalities such as fire or gas leaks in real time. We are also equipped with a prompt response system on all accidents, operating emergency reporting phones at various places in the factory with signs indicating locations for the purpose of promptly identifying the location of accidents at a wide range of locations.

-

[Operation of situation room in integrated disaster prevention center]

[Operation of situation room in integrated disaster prevention center]

-

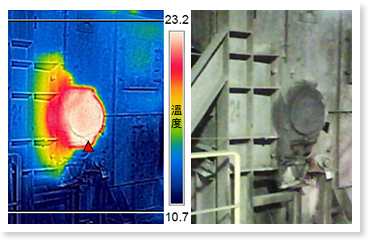

[CCTV + thermal image monitoring]

[CCTV + thermal image monitoring]

-

[Installation of signs indicating locations]

[Installation of signs indicating locations]

-

-

Emergency Rescue / Early Extinguishment of Fires

We have a chemical fire engine, a retractable fire engine, and an ambulance for early response to the scene of an accident while operating a company fire brigade where professionally trained firemen and emergency rescuers are permanently stationed. Having set up an emergency response system for each factory, we perform simulated emergency response training periodically in connection with the firemen while performing fire extinguishment/evacuation training with the participation of all employees in order to secure the ability to cope in the event of fire. We are making efforts to prevent spread of accidents due to failed normal operation of firefighting and gas facilities by regularly performing self-regulated inspections in addition to legally mandatory inspections on firefighting and gas facilities.

-

[Emergency response training]

[Emergency response training]

-

[Training in emergency rescue]

[Training in emergency rescue]

-

[Consolidating the coping ability of independent fire brigades at each department]

[Consolidating the coping ability of independent fire brigades at each department]

-

-

Recovery / Recurrence Prevention

We are setting up emergency recovery and recurrence prevention plans through an arrangement between the department where an accident has occurred and the related departments by holding a recurrence prevention meeting after the accident. Emergency recovery plan is set up by analyzing production equipment, utilities, electricity, building, and safety facilities in many aspects, so that the production can be normalized within a short period of time by sharing the recovery situation. We are managing effectively by clarifying the precise fundamental cause of an accident to set up and implement a comprehensive safety plan addressing facilities improvement, training and work improvement, etc. to prevent the same type of accident from repeating.

-

[Emergency recovery]

[Emergency recovery]

-

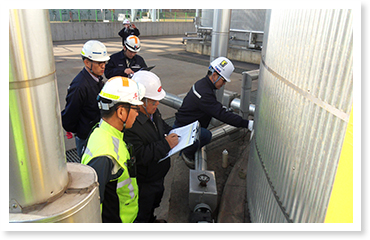

[Investigation of cause]

[Investigation of cause]

-

[Recurrence prevention meeting]

[Recurrence prevention meeting]

-