S.H.E.

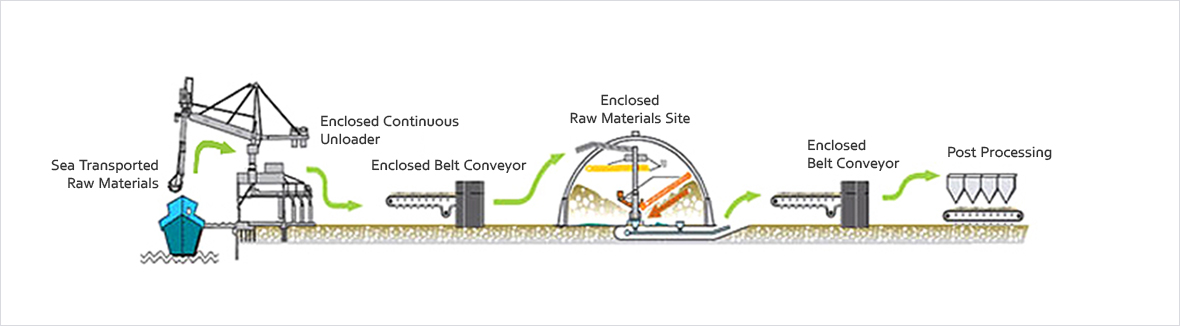

Raw Material Processing Facility Flow Chart

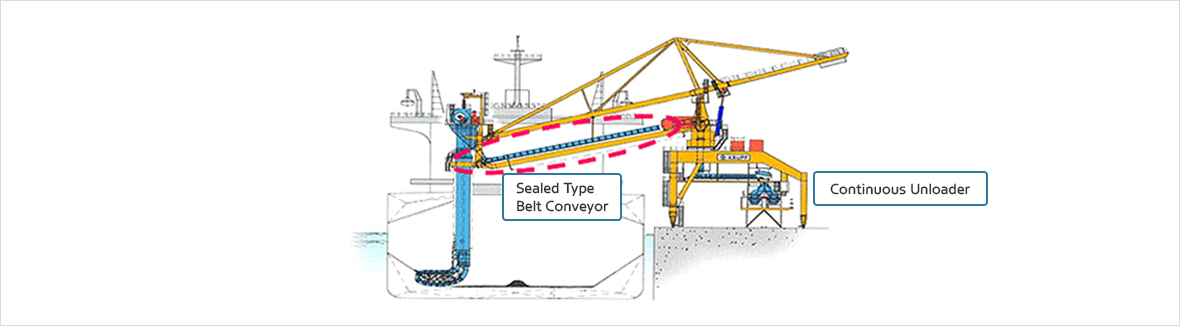

Enclosed Unloading Equipment

-

- Equipment Overview

- Equipment that continuously unloads raw materials from the ship that has approached the pier

-

- Effects

- Prevents scattering dust and dropping ore

Enclosed Belt Conveyor

-

- Equipment Overview

- An equipment that supplies unloaded raw materials to the storage facilities or follow-up processes such as sintering, cokes, limestone calcination, and blast furnace

-

- Effects

- Minimizes scattering dust

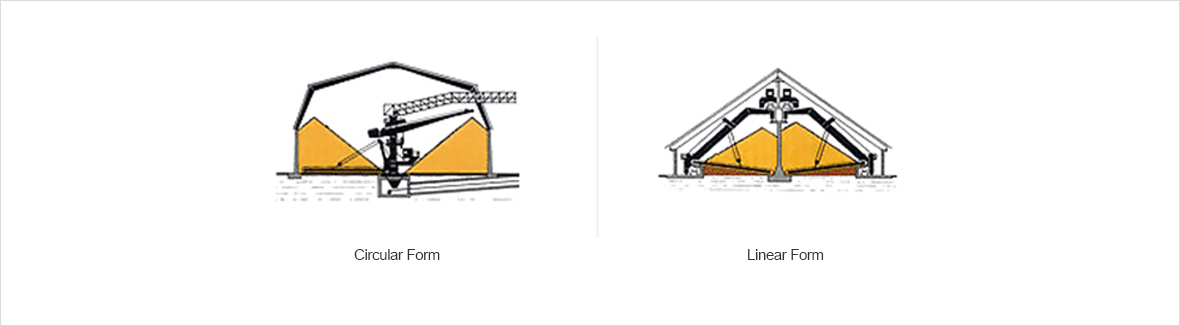

Enclosed Raw Materials Storage Facility

-

- Equipment Overview

- A circular or linear enclosed raw materials treatment facility storing the raw materials unloaded from the raw materials pier

-

- Effects

- Minimizes creation of scattering dust and muddy water

Slag Processing Equipment

-

- Equipment Overview

- Equipment that recovers base metal by crushing/fineness sorting the blast furnace and steel making slag to produce slag aggregates for engineering work and for concrete

-

- Effects

- Recycling of the slag created from the steelworks

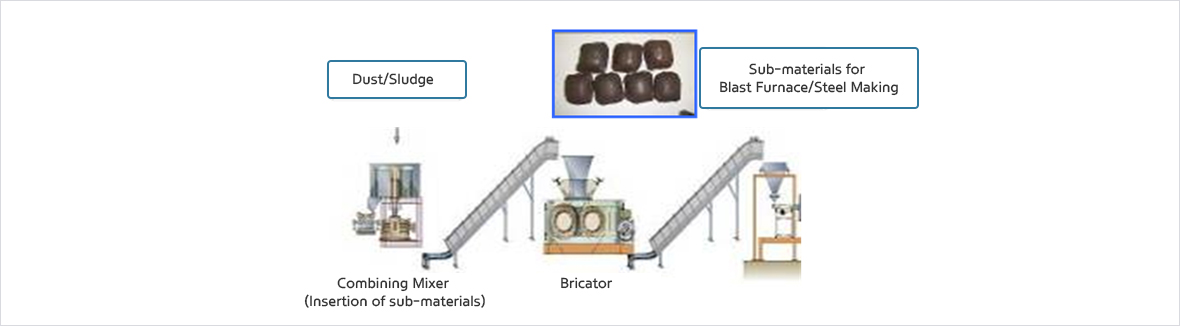

Briquet Forming Facility

-

- Briquette Molding Equipment

- Equipment that molds dust or sludge that has recycling value to be used as substitution materials for steel making ingredient

-

- Effects

- Reinvigorated reuse in process of the by-products created at the steelworks

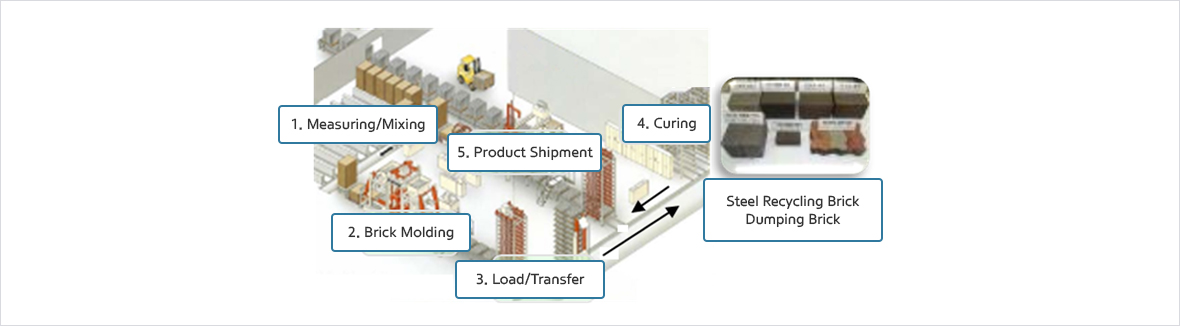

Brick Molding Equipment

-

- Equipment Overview

- Equipment that recycles dust or sludge created from the steelworks, or molds them properly for uses such as dumping or burial

-

- Effects

- Reuse of by-products in the process and safe processing

Self-Contained Burying Equipment

-

- Equipment Overview

- Equipment (managed burying facility) that safely disposes of wastes that cannot be recycled any more or designated wastes that include harmful ingredients

-

- Effects

- Safe disposal of harmful wastes